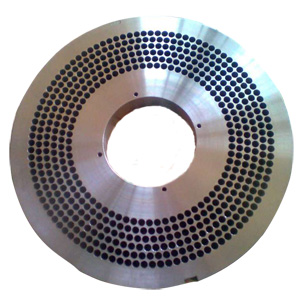

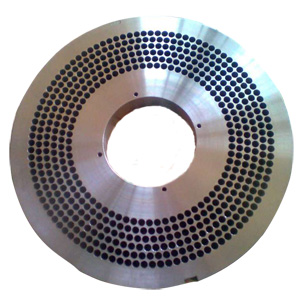

pellet mill die

Pellet mill flat die is a key spare parts for flat die pellet mill. Compared with other manufacturers, flat dies from GEMCO adopt high content 40Cr to increase wear-resistance. The material of flat dies is forging, while internal grain is more fine and uniform so as to improve the mechanical properties.

The flat die holes distribute evenly and smoothly. It is apt to make high quality pellets and improve capacity.

|

|

|

|

The Salient Feature of Pellet Mill Flat Die

♦ After tempering, 40Cr has good mechanical properties and is wide-used quenched and tempered steel.

♦ Application for shaft parts and crank, automotive steering knuckles, connecting rods bol, gears etc.

♦ Table hardness48~55HR. Under 50mm cross-sectional dimension, after oil quenching, it is a higher fatigue limit. Under certain conditions available for 40MnB、45MnB、35SiMn、42SiMn etc.

|

Our flat die has high quality and good fame, due to professional processing and strict inspection.

|

|

|

The whole process of flat die |

The flat die holes inspection |

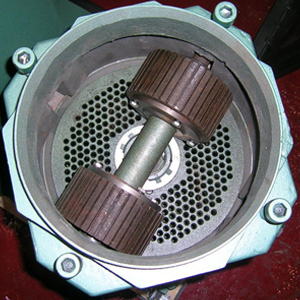

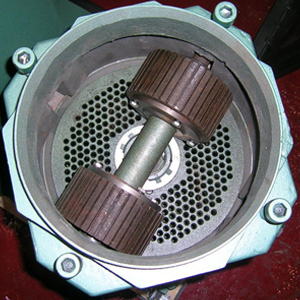

Application of Pellet Mill Flat Die

Good quenched and tempered steel with good comprehensive mechanical properties is widely utilized for important and overload situations like crank shaft, universal joint and spindle etc. By special heat treatment process, the hardness can reach 60 HR, which improves the wear resistance. And high intensity of heart and good overall strength.

Professional Rigidity of Flat Die Inspection