flat die pellet mill

Flat die pellet mill has a horizontal die with a series of rollers on the die, which is mainly used for small scale pellets production. The raw materials are fed from the top and pressed between press roller and die. There are two designs of flat die pellet mill: the one has a rotating roller with a stationary die, it is called rotating roller pellet mill; the other has a rotating die with a stationary roller shaft, it is called rotating die pellet mill. While the rotating roller pellet mill is much more popular.

|

|

|

The rotating roller pellet mill is rotating roller with a stationary flat die. |

The rotating die pellet mill has a stationary roller with a rotating flat die. |

First, we will introduce different details between them.

The Design of Rotating Roller Pellet Mill

Active rotating roller is conducive to press materials, drive materials movement and promote the stirring of the material. The large diameter of press roller shaft is able to withstand the reaction force of hardwood etc. not easy molding material. Lower molding speed reduces the sensitivity to materials and be better adaptability for different materials.

The Internal Structure of Rotating Roller Pellet Mill

The rollers rotate to press materials while the flat die is stationary settled by a spindle. Usually rotating roller pellet mill is suitable for processing wood pellets.

The External Appearance of Rotating Roller Pellet Mill:

|

|

|

The structure: Welded frame body structure, overall strength, and good stability. |

Rotating die pellet mill is different from rotating roller pellet mill in design greatly.

The Design of Rotating Die Pellet Mill

Flat die rotates and drive the materials and press roller moving at the same time. In this kind of composite motion, the materials can be gone into the compression area sufficiently and it is conducive to make feed pellets.Simple supported structure of press roller shaft is good to withstand larger deformation resistance. High forming speed improves the product yield and reduce energy consumption.

The Internal Structure of Rotating Die Pellet Mill:

The flat die rotates to drive the materials while the press roller is stationary settled by the bearings.

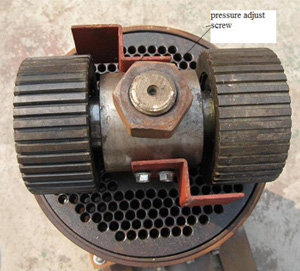

The External Appearance of Rotating Die Pellet Mill:

|

|

|

The structure: Casting structure can receive the work vibration and reduce noise effectively. |

Other auxiliary spare parts of flat die pellet mill

Bearings: All bearings we adopt sealing structure to prevent dirt and improve the working environment of bearings and prolong bearings life are the high quality in China.

Spindle:

Spindle: Spindle is made from alloy steel by carburizing after the fire with strong abrasive resistance.