There are so many different types of pellet mills, all manufactured by different manufacturers. As such, pellet mills are therefore made up of different parts, assembled together to make sure that they are working just fine. If you own a pellet mill, one of the things you are required to do is to know what the main pellet mill parts are, so that you can enhance maximum output and increase the lifespan of the machine.

Parts of

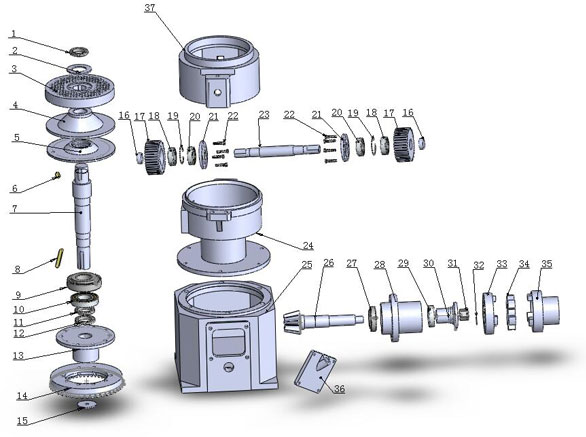

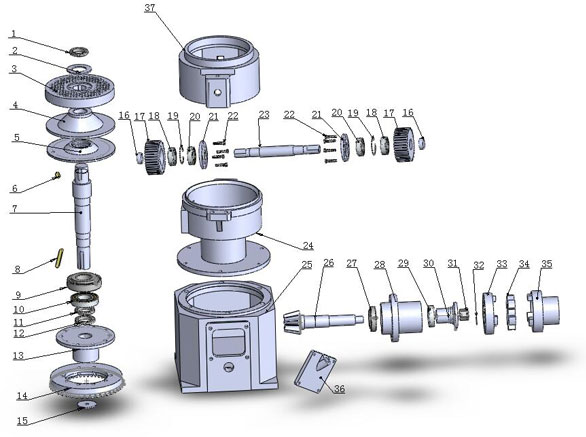

As different pellet mills contain different spare parts, a single pellet mill also consist of various parts that will play together to enable the machine to run. Take the flat die pellet mill as an example,

rollers and

dies should be the most important pellet mill parts.

| Item | Description | Qty |

|---|

| 1 | Round nut | 1 |

| 2 | Flat Pad | 1 |

| 3 | Die | 1 |

| 4 |

Disc of throwing stuff | 1 |

| 5 | Dust cover of principal axis | 1 |

| 6 | Flat key of type A | 1 |

| 7 | Principal axis | 1 |

| 8 | Flat key | 1 |

| 9 |

Tapered Roller Bearings 30309 | 1 |

| 10 | Bearing 6208 | 1 |

| 11 | Round nut | 1 |

| 12 | Round nut | 1 |

| 13 | Big gear seat | 1 |

| 14 |

Big gear (43) | 1 |

| 15 | Check Ring for axis | 1 |

| 16 | Check Ring | 2 |

| 17 | Pressing Roller | 2 |

| 18 | Bearing 6205 | 2 |

| 19 | Check Ring for Hole | 2 |

| 20 | Bearing 6205 | 2 |

| 21 | Bearing Cover of press roller | 2 |

| 22 | Hexagon Head Screw | 8 |

| 23 | Wheel Shaft | 1 |

| 24 | Spindle Box | 1 |

| 25 | Gear Box | 1 |

| 26 | Gear Shaft | 1 |

| 27 | Tapered Roller Bearings 30207 | 1 |

| 28 | Pinion Seat | 1 |

| 29 | Bearing 6206 | 1 |

| 30 | Splined sleeve | 1 |

| 31 | Castle Nut | 1 |

| 32 | Cotter Pin | 1 |

| 33 | Passive Coupling | 1 |

| 34 | Elastic Cushion | 1 |

| 35 | Active Coupling | 1 |

| 36 | Cover of observation window | 1 |

| 37 | Upper Box body | 1 |

Under normal circumstances, the flat roller will be responsible in making sure that the end product is of good quality. This pellet mill part is designed to provide rough surface like environment to the material so that traction can go on well. A flat die pellet press is manufactured with at least two or three flat rollers that operate inside the die. A pellet mill is made up of many pellet mill parts all of which are primary in its function and hence enable the pellet mill to provide admirable pelletizing results. There is the die, the rollers as well as the knives which are pellet mill parts responsible for cutting the pressed pellets to the required sizes. In order to manage pelletizing procedure in terms of die and roll management, the entire theory of operation of the pellet mill should be understood and thus why it is also necessary to understand what is needed in terms of roller sizes, the number, and assembly among other reasons.

As the basic pellet mill parts of this machine, dies are widely used in the process of making wooden pellet. The importance of getting a good die for your pellet pressing machine cannot be overstressed, as the die comprises the basic part of the machine. To flat die pellet mills, the flat dies are their ideal pellet mill part rather than the ring dies. They are available in many different designs such as the fixed die which is equipped with a rotating roller or you can opt for a fixed roller with a rotating die. Consider the choice of your raw material to be used in making the pellets.

What Can We Offer You?

GEMCO specializes in pellet equipments and components manufacturing and supplying. We can offer you standardized pellet mill parts which enable you replace rollers and dies with ease, dismounting devices and grease gun for lubrication. With our pellet mill parts and services, you can fully optimize the function of pellet mills.

A. We supply free instruction of how to operate pellet mills correctly to help you prolong the usage life of your quick-

wear pellet mill parts.

For many people, they are not familiar with their pellet mills and parts. When they operate the machine, it could be treated incorrectly. This might conduct a very easy wear and tear of pellet mills. We can help you freely and give you some instruction and suggestion, so that the pellet mill can work better for you.

B. We can supply you adequate quick-wear pellet mill parts.

Pellet mill parts manufactured and supplied by our company varies according to different machines and different processing need of raw materials. We dedicate to provide good quality parts to you, so that you won’t worry about the interrupt of your pellets production.

C. Our pellet mill parts are superior in many aspects. Quality inspector is testing the intensity of pellet mill roller die.

- Patents of GEMCO make the pellet mill parts perform better, like the distribution of die holes, both sides of the die can be used, etc.

- Professional quality department promises each part of pellet mills can meet the quality standards.

- Alloy steel made components strengthens the durability of machine and prolongs the usage life of pellet mills.

- Heat treatment to main components makes surface of main components not easy oxidized.

- Length and diameter of pellets are adjustable with different dies for meeting your different needs.

- Large- scale and timely supply of our pellet mill parts is available.

Do You Know

How to Maintain the Pellet Mill Replacement Parts?

By considering most of the pellet mill parts mentioned above, now you know that the pellet mill has many moving parts. Some parts experience minor problems such as jamming and that tends to directly affect the overall output of the pellet mill. Such jamming can be avoided successfully by ensuring that there is a regular lubrication practice especially on the movable parts of the pellet mill.

When you carry out proper maintenance of pellet mill parts, you will not only be sure of good quality pellets but you will also save a lot of money that you would otherwise have used to buy costly spare parts. Special attention should be given to the roller and the die as they form the basic accessories for the pellet mill.

Make sure to clean the roller and the die regularly.

No accumulation of foreign materials remaining in the space between pellet mill parts is allowed. Good space must be maintained between the die and the roller to reduce friction. Ensure that both the speed of the roller and the die are correctly set to minimize wear and tear.

Make sure to lubricate the machine regularly.

High priority should be accorded to all flat die pellet mill parts that will run in pelletizing by ensuring they are intensely lubricated for ease of movement. The first time you use the flat die pellet mill, you should lubricate the machine sufficiently. Then you can check them and do lubrication every few months to make them work normally.

To pellet mill parts of rollers and dies, before the first time using, you can mix sand, oil, and some other material according certain quotation, then start the machine and put these materials into it. So you can finish the lubrication of roller and die. After this time, you can add some lubrication oil to the machine as the parts need.